Non-Destructive Testing (NDT)

Non-destructive testing (NDT) services are essential for the marine industry, ensuring the safety, reliability, and longevity of vessels and offshore structures without causing any damage to the materials being inspected. These services are crucial for detecting and evaluating flaws, ensuring compliance with industry standards, and maintaining operational excellence.

Hull Surveys & Thickness Measurement (UTM):

We provide expert Ultrasonic Thickness Measurement & Hull surveys services for vessels (steel, aluminum) and composite structures of all types to ensure the safety and structural integrity of your assets by checking both hull thickness and any hull defects or damage that may be present by using advanced equipment such as the CYGNUS 4+ UTM equipment. Consult Maritime also provides a range of related services, including inspection plans, life extension studies, dry-docking, and conversion. Our team of qualified technicians follows recognized industrial NDT standards and undergoes regular training to ensure accurate and reliable measurements

We provide clients with a detailed report that includes the original design thickness, current thickness, percentage of material loss due to corrosion, and locations of critical areas.

Thermal Imaging:

These services use infrared cameras to detect temperature variations in materials and components, providing valuable insights into the condition of the vessel's structure and systems.

Thermal imaging can be used to evaluate mechanical and electrical systems, identifying hotspots or inefficiencies that may indicate potential issues such as overheating, excessive resistance, or faulty components. It is also useful for inspecting insulation and HVAC systems, ensuring optimal performance and energy efficiency.

The process involves a comprehensive survey that covers various areas of the vessel, including mechanical and electrical system evaluation, insulation and HVAC system inspection, and leak detection. The results are compiled into a detailed report with high-resolution images and expert recommendations for addressing any identified concerns

Visual Inspection:

This service involves a thorough visual examination of welds to identify any defects or irregularities that could compromise the integrity of the structure.

Dye Penetrant Inspection (DPI):

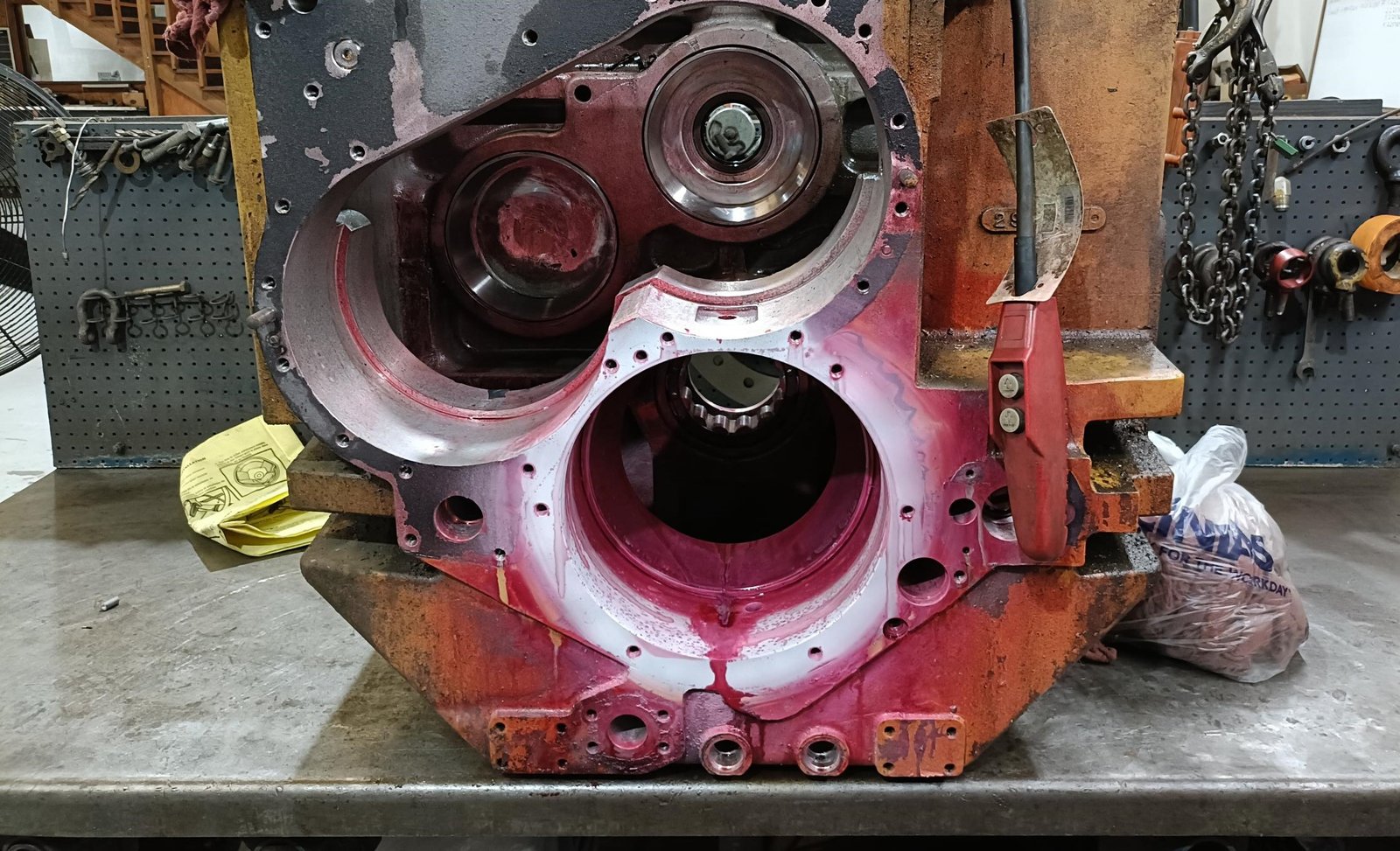

This method is used to detect surface-breaking defects in non-porous materials. It involves applying a liquid penetrant to the surface and then using a developer to draw out any defects.

Magnetic Particle Testing (MPT):

This technique is used to detect surface and near-surface defects in ferromagnetic materials. It involves applying a magnetic field to the material and then using magnetic particles to reveal any defects.